Description

Equipment Overview

Well-maintained Stewart Bolling 200 Ton heated platen press, recently decommissioned. Control systems and pump motor replaced ~3 years ago; platens resurfaced; minimal pneumatic/hydraulic issues. Ideal for composite, rubber, or flat sheet forming.

Key Features & Specifications

200 US Ton hydraulic press, up‑acting configuration

Electric-heated top and bottom platens: 24″ W × 34″ D × 9″ T

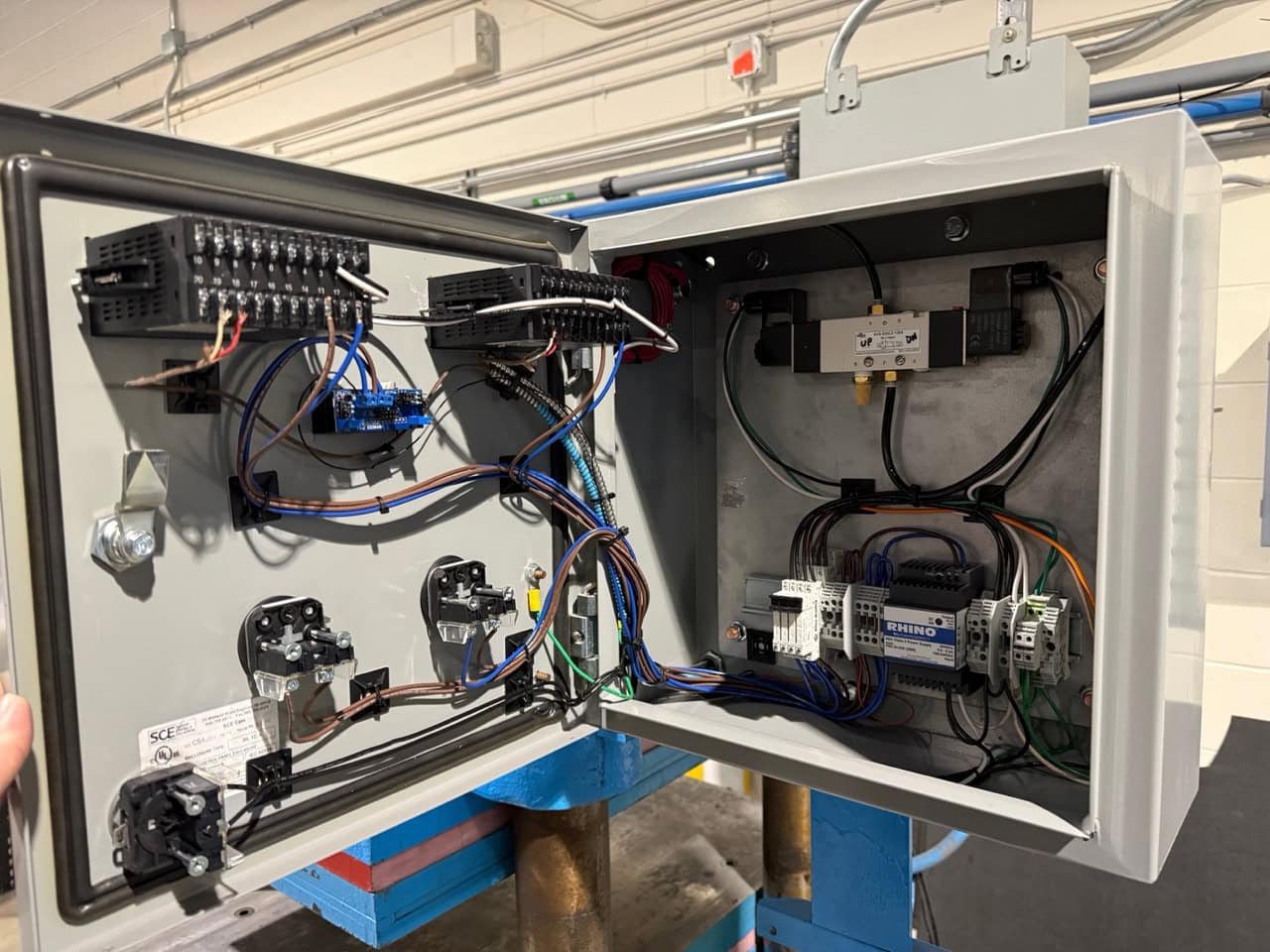

Modern control panel: digital temperature controllers for both platens, manual raise/lower, emergency stop

Hydraulic power unit: replaced pump motor and internal gear pump (approx. 3 years ago)

Platens resurfaced flat within tolerance during last refurbishment

Pneumatic valve slowly bleeds pressure; minor o‑ring leaks at selected fittings only

No external chiller or oil circulation loop included or used

Minimal prior use dedicated to composite material pressing; low mechanical wear profile

Structurally sound: cast frame with no observed cracks; clean storage condition

Electrical upgrade: new transformer, relay/contactors, wiring control cabinet