Description

Machine Overview

This Nol-Tec powder handling system is a dual-tower configuration supporting polyester powder transfer from bulk bag unloaders through surge hoppers, loss-in-weight feeders, and rotary valves into a dilute phase pneumatic line. Both systems are identical and operate independently with separate destinations. Designed for precise powder metering, the system integrates Brabender LIW feeders, Siemens-based PLC control, and full air and rotary valve interface.

Specifications & Features

Two (2) complete BBU + LIW transfer towers with dilute phase pneumatic transfer

Polyester powder handling design; 43.7 / 87.4 lb/ft³ density, 30 micron particle size

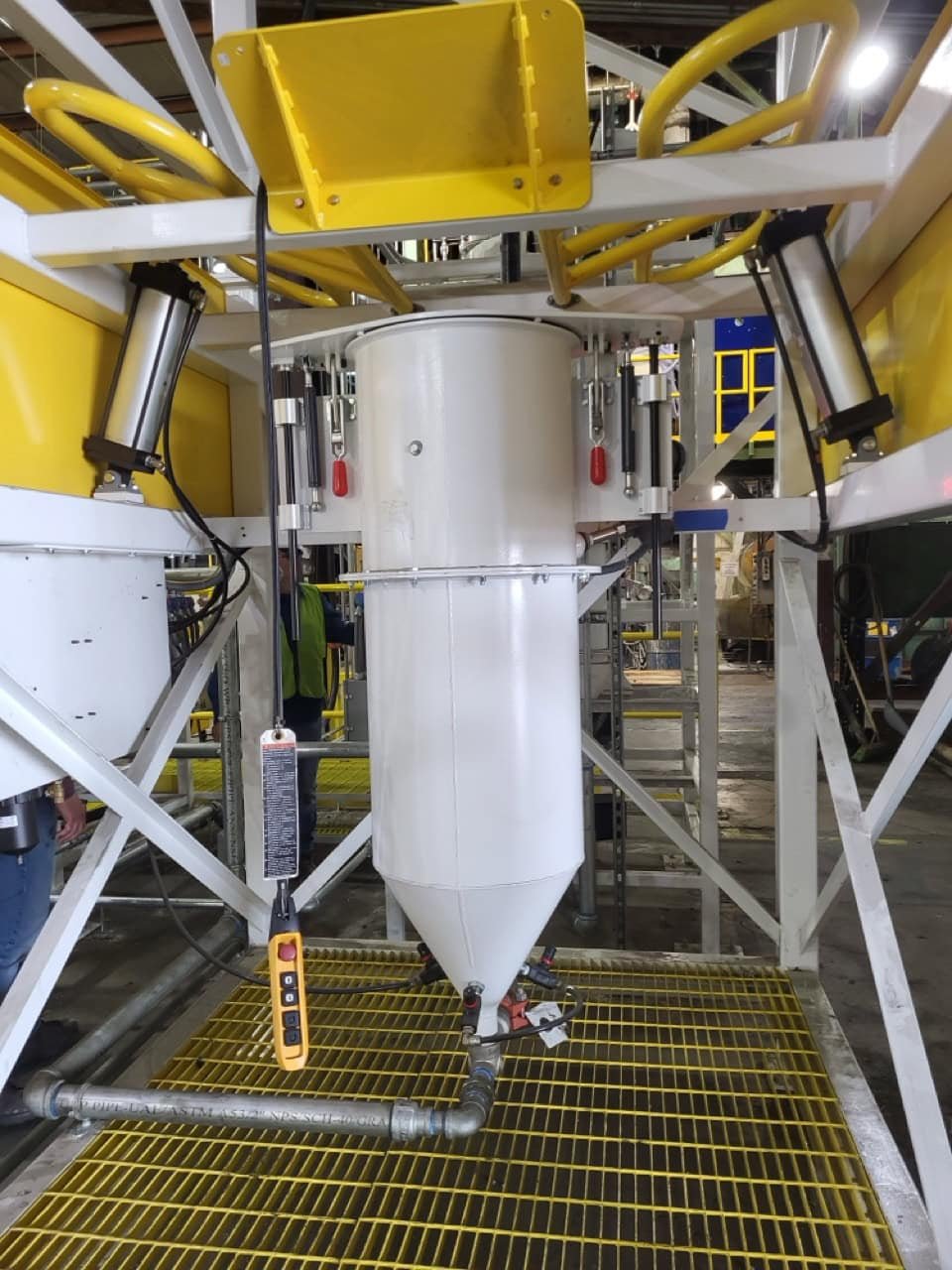

Bulk Bag Unloaders (Model 348 hoist-style, 2-ton certified):

– Electric hoist, pendant control, bag spout seal, agitator, surge hopper, educator

– 4 cu. ft. surge capacity, level probe, aeration

Twelve (12) single-bag dust filters with polyester media and pulse valve

Loss-in-Weight Feeders (Brabender, Qty 2):

– Polyurethane trough, 200L hopper, Class II Div 2, external agitator

– Load cell system, high-level probe, spare screw/tube, stainless contact parts

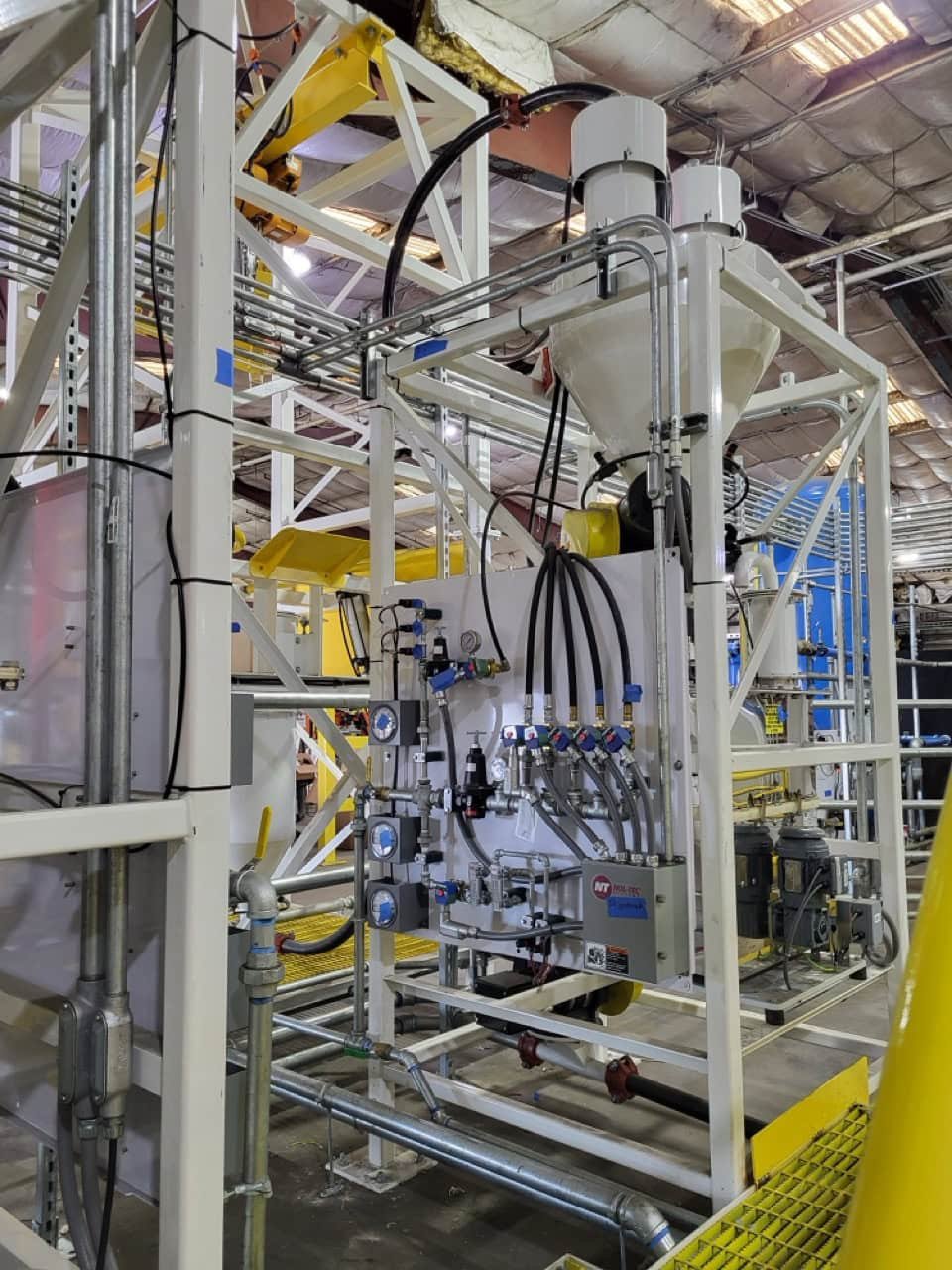

Rotary Valves (Qty 4):

– 8″ (.18 CFR) and 6″ (.07 CFR) cast iron, chrome-plated, ¾ HP gear motors

– Outboard bearings, air purge seals, quick-clamp adapters

Dilute phase pressure conveying system (2″ line, 10’ vertical, 40’ horizontal, 3 bends)

Design transfer rate: 330–1200 PPH (Tower 1); 1800 PPH (Tower 2)

Secondary air control panel: solenoids, regulators, transmitters, gate valves, servo regulators

Main Control Panel (Siemens):

– S7-1200 1215C CPU, I/O, analog modules, HMI 12″ Comfort Panel

– Siemens G120 VFDs with ProfiNet, weigh scale indicators

– 24VDC supplies, Ethernet switch, programming port, isolation relays

– Allen-Bradley breakers, fuse blocks, terminals

All towers and components built on mild steel support frames