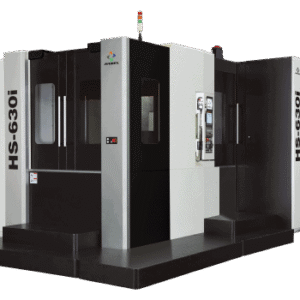

Description

Max. machine capacity: 43.31″ x 36.22″ x 31.50″

Travel:

X-Axis: 43.31″

Y-Axis: 39.17″

Z-Axis: 32.50″

Spindle center to table (pallet) upper surface: -2.95″ to 36.22″

Spindle end to table (pallet) center: 9.84″ to 41.34″

Table:

Table (pallet) size: 31.50″ x 31.50″

Index positions: 360 positions (1 degree increment, direct command)

Load capacity: 3,300 lbs.

Spindle:

Taper hole: NT No. 50

Spindle diameter (at front bearing): 3.94″

Spindle speed range: 30 to 3,600 RPM

Number of spindle speeds: Infinitely variable

Feedrate:

Rapid traverse (X, Y, Z Axis): 512 IPM

Jog feedrates (X, Y, Z Axis): 0.01 to 157 IPM

Tool magazine capacity: 50 tools

Tool selection: Random (fixed address)

Tool shank system: MAS BT50

Pull stud bolt type: MAS Type II

Max. tool diameter:

With adjacent tools: 5.51″

Without adjacent tools (face mill cutter): 9.06″

Boring tool: 11.81″

Max. tool length: 15.75″

Max. tool weight: 44 lbs.

Machine height: 124.02″

MOTOR SPECIFICATIONS:

Main motor: 20

Hydraulic power unit: 9.3 HP

X-Axis drive: 4.8 HP

Y-Axis drive: 4.8 HP

Z-Axis drive: 6.4 HP

-Table indexing: 0.5 HP

Equipped With:

• Rigid tapping control

• Dual control display

• Additional setup and control functions for machine ease of operation

• Additional control group to run tool changer axis asynchronous to main axis group

• MTConnect interface for machine data exchange with customer’s Management Information System