Description

A.P.E.S. Explosion Proof Liquid Filling Line, 2021 – NEVER USED, Still on OEM Skidding

– Intended use was for hand sanitizer

36″ rotary feed table

– 304 stainless steel construction with leveling pads

– Single 304 stainless steel rail system

– Stainless steel guide rail brackets

– Variable speed DC drive controls wired into filler control panel

– 120/240VAC / 1 phase / 50-60Hz

30′ Intrinsically-safe Filler Conveyor

– 304 stainless steel construction with leveling pads

– 4.5″ wide static dissipative belt

– Dual 304 stainless steel rail system with anti-static wear strip material

– Stainless steel guide rail brackets

– Hazardous location rated 90Volt DC ½ HP Leeson motor (Class I, Div. I Groups

C&D)

– 36:1 gearbox for speed rates up to 70 ft./min

– Variable speed DC drive controls wired into filler control panel

– 120/240VAC / 1 phase / 50-60Hz

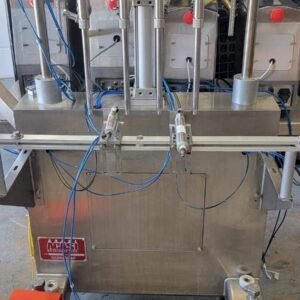

14 Head Automatic Pressure/Gravity Filler

– 304 stainless steel heavy-duty frame construction with adjustable leveling pads

– 316 stainless steel 3/4″ pneumatically actuated fill head assemblies

– Wire reinforced PVC product tubing with stainless steel hose barbs

– (2) 304 stainless steel pressurize product reservoir with 316 stainless steel level

sensing dual ball float for safety back-up. Includes digital pressure controller,

pressure gauge, pressure relief valve rated for 15 psi, manual throttling valve and

necessary hardware

– (2) 1.5″ stainless steel product supply control valves

– Low head pressure/no fill system controls

– User-friendly Allen Bradley/MicroLogix 1200 PLC controls with 6” Maple

Systems with color touch screen which offers user-friendly setup capabilities and

50 job recipe storage capability

– All level sensors and photo sensors will include intrinsically safe barriers to

provide milliampere signal to and from PLC

– Stainless steel stand to allow filler control panel to be remotely mounted away

from filler

– Automatic bottle neck locators to ensure proper bottle alignment beneath fill

heads

– Automatic drip tray protects bottles from potential drips

– Automatic star wheel indexing to bring bottles in and out of fill station – includes

double-stacked star wheel for 12 oz. container

– No Bottle/No Fill sensor to ensure proper bottle count prior to filling

– Anti-bottle back-up sensor to pause filling cycle if downstream jam is detected

– Manual crank height adjustment for fill heads

– Supply pump and motor starter not included

– NEMA 12, painted steel enclosure

– Requires clean, dried air at 80-100Psi

– 120/240VAC / 1 phase / 50-60Hz

Fully Automatic 4-Station Spindle Capper

– 304 stainless steel frame construction with castor wheels and leveling pads

– 304 stainless steel and anodized aluminum components

– 304 stainless steel cap sorting elevator

– Anodized aluminum cap chute, tool-less adjustment for easy changeover

(accommodates cap diameters from 20mm – 110mm

– Variable speed drive controls for spindle wheels and gripper belts

– Mechanical friction clutch torque control on 3rd & 4th spindle set

– Spring loaded poly cap stabilizer

– Automatic full chute pause sensor

– Power height adjustment

– Dual 3/4″ gripper belts. Includes toolless adjustment vertically and horizontally

– Independent base designed to mount over existing conveyor

– 120VAC/1 phase/50-60Hz