Description

A Packaging Systems Fully Automatic Filling and Labeling Line for Shampoo Bottles, 2009:

Previously used primarily for 1 and 2 oz bottles with wrap label or two side label. Can be used to full up to a gallon.

A Packaging Systems Filler:

Positive Displacement Pump Filler Module

– Sturdy stainless steel tubular frame on adjustable leveling legs and casters

– Easy height adjustment up to 12″ tall containers

– Stainless steel filler reservoir

– Filler product re-supply system with electronic float system and check valve

– PLC Control System with digital LCD touch screen display

– Digital filling volume setting for each pump from touch screen.

– Revolution sensor-based pump RPM pulse counting system.

– Automatic bottle indexing system (moves bottles automatically)

– No bottle/no fill vision system (insures no attempted fill of missing bottles)

– Anti-bottle backup vision system (prevents filling if bottles are jammed downstream)

– Overall electronic production counter

– Pneumatic gates to stop containers or Star wheel bottle indexing.

– Conveyors start/stop control system.

– Memory locations for fill and indexing set-up recipes

– Pump & Drive System: Variable Speed Motor, Gear Reducer, Clutch/Brake, and stainless-steel positive

displacement pump.

– Bottom close stainless steel nozzle assembly

– Automatic Neck Locating System

– Diving Head Mechanism with Air-actuated operation

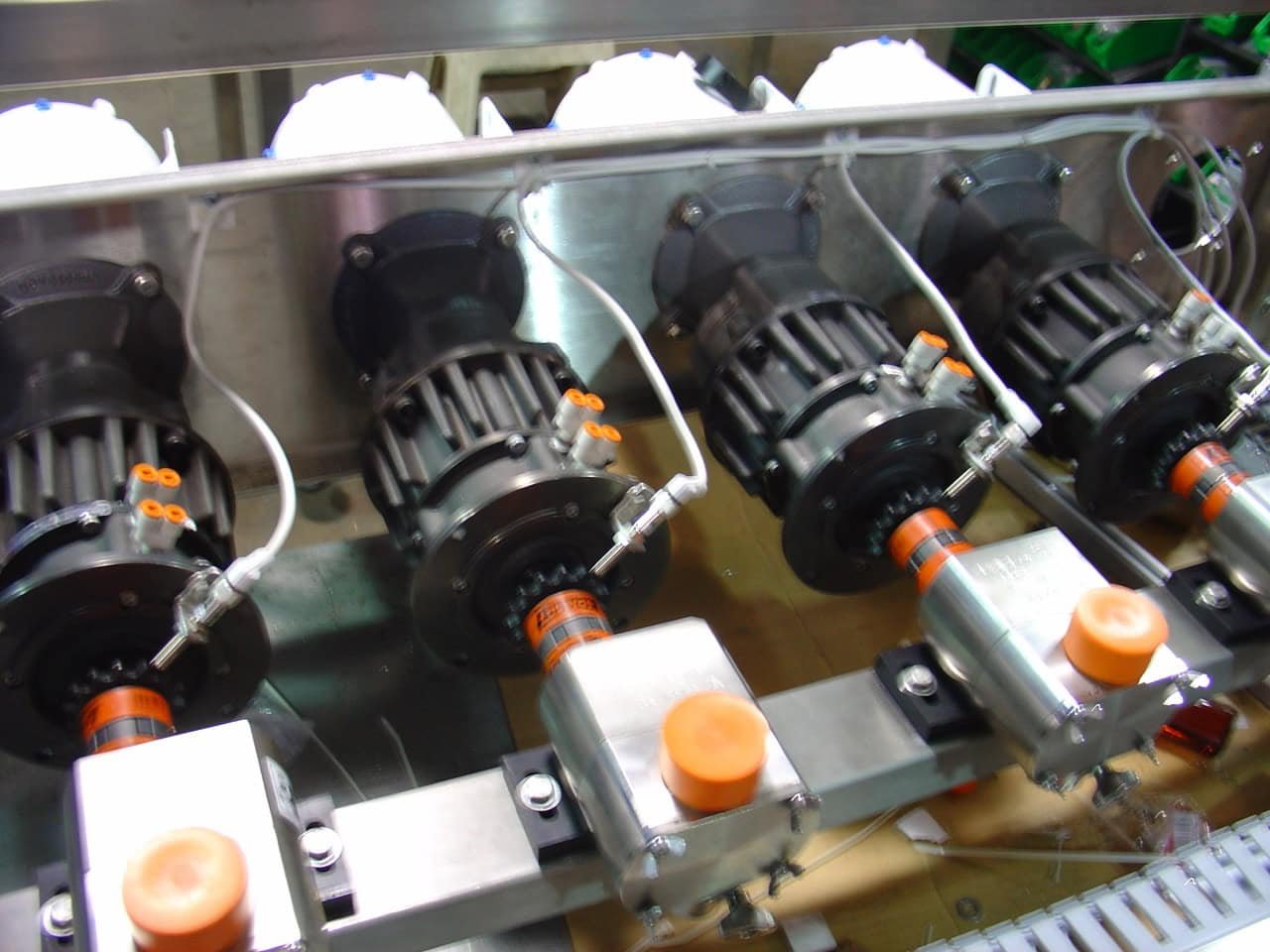

A Packaging Systems Inline 6 Spindle Cap Tightener

– Fully adjustable for caps from 8 mm to 110 mm

– Fully adjustable from 1 inch to 14-inch-high containers

– Heavy duty 304 Stainless steel Tig-welded C frame

– 6 capping discs, with bottom screws change over.

– Direct gear motor transmission through coupling for capping belts movement

– DC gear motor for independent speed control of gripper belts

– Capping discs adjustment by frontal knobs, with lock nut hand wheel

– Hand Crank for manual height adjustment

– Gripper belt in/out adjustment by hand wheel

– Priced with single, opposing, 3/4″ Gripper Belts (other models available)

– No change parts needed for a wide range of containers.

– Electric and pneumatic requirements: ·110 Volts, 60Hz, 15 Amps. ·5 CFM @ 80 p.s.i.

– Cap Delivery Chute, tool-less adjustment on 4 axes for versatility, can be fed manually or by automatic sorting system.

CEI 27″ Vibratory Cap Sorting Bowl

– 27″ Bowl diameter with 304 stainless steel construction, tooled for various caps.

– Alternating Vibration Coil and Control Cube, for adjusting sorter speed.

– Heavy-duty Bowl Cart, with powder-coated steel frame, leveling legs and casters.

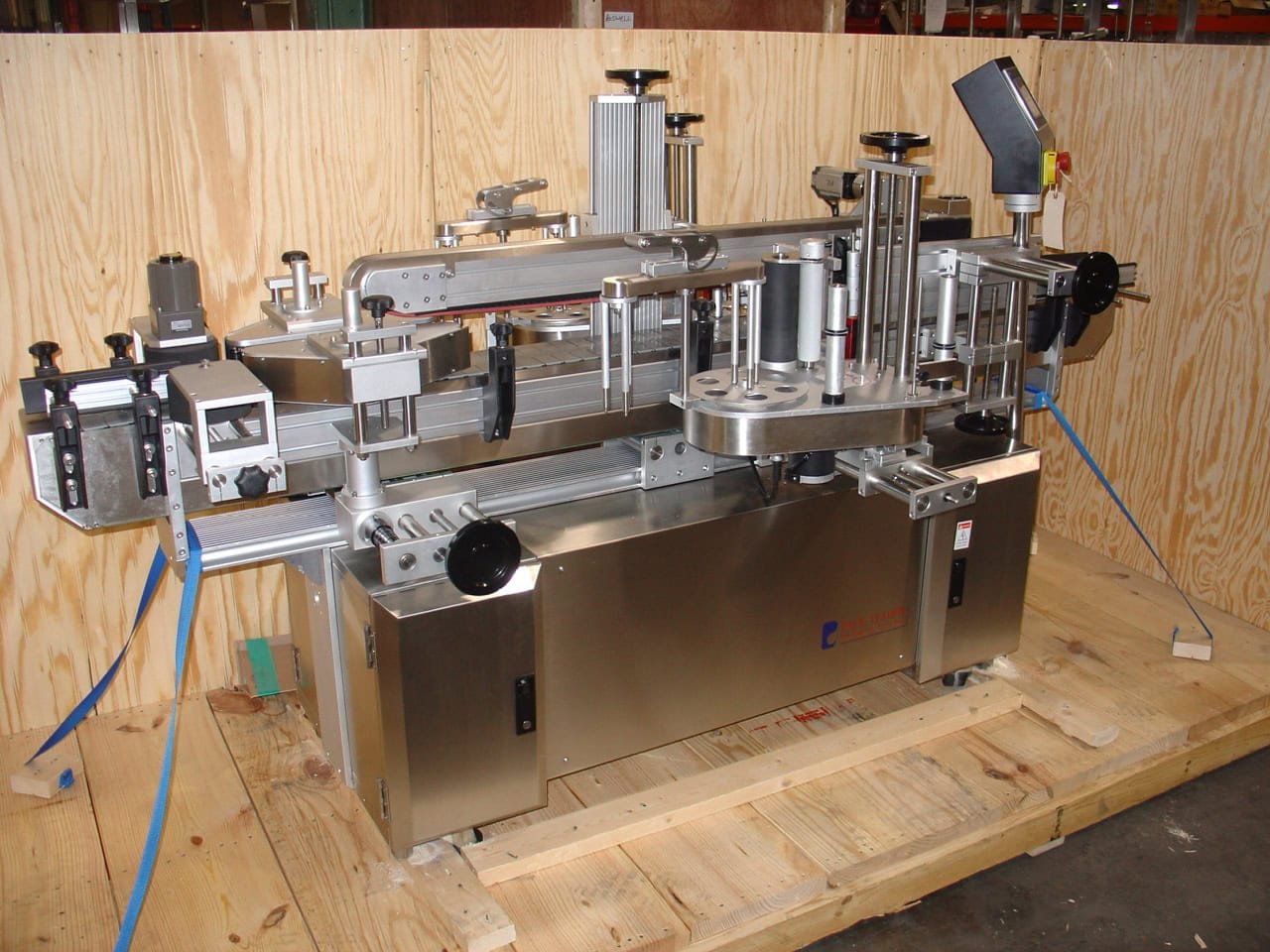

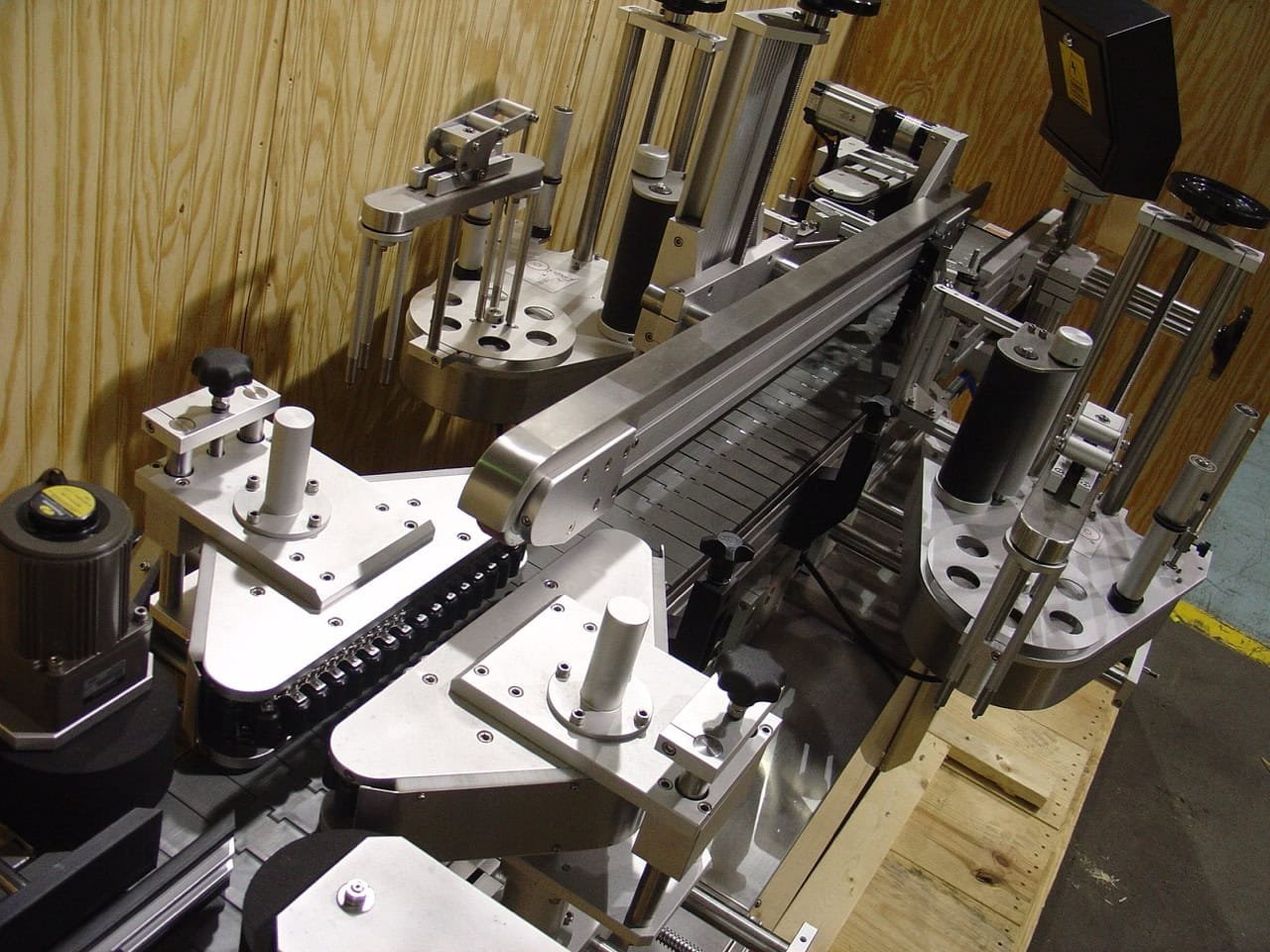

Pack Leader Pro-625 Front and Back Pressure Sensitive Labeler with Wrap Station Feature

– The automatic front & back labeling system comes equipped with a 6

5/16″ inch wide (adjustable) X 8’ long variable speed conveyor.

– Features include a stepper motor drive for label and power assisted web take up

– Labeling heads speed automatically synchronizes with conveyor speed.

– Non-contact photo eye sensors and an auto teach function for new labels.

– Handles many different size containers and can be used in virtually all industries such as

pharmaceuticals, personal care products, foods, vitamins, cosmetics, and chemicals.

– One touch automatic label detection and setup

– Built-in touch screen operation manual

– Built-in touch screen troubleshooting guide

– Low or Missing label detection with automatic stop system to prevent mislabeling.

– Label counter and Count down feature to allow precise run of set number of labels.

– Auto Shut Off

– Specifications: Voltage: 220/110 VAC 50/60 HZ 1 phase Power: 1,320 WA

– Conveyor speed: 0-40m/min.

– Dispensing speed: 40 m/min max.

– Applicator height: 150mm(5 7/8″)/200mm(7 7/8″) Conveyor width: 160mm (6 5/16″)

– Spool diameter: 76mm(3″)

– Measurement: 2,420mm (L)*1,800mm(W)*1,450mm(H)

– Full or Partial Wrap Labeling Feature

A Packaging Systems Turntables

1 APS 40″ ACCUMULATING TURNTABLE

– 304 stainless steel Disc top

– 304 stainless steel frame construction

– Line height 30-36″

– Clockwise or Counterclockwise rotation

– 115/230Volt/1f/50-60Hz Variable speed control box mounted on machine cabinet

– Single rail system with HDPE bottle contact surface and tool-less adjustments

(1) A Packaging Systems 40″ LOADING TURNTABLE

– 304 stainless steel disc top

– 304 stainless steel frame construction

– Overhead support system for bottle diverter

– Line height 30-36″

– Clockwise or Counterclockwise rotation

– 115/230Volt/1f/50-60Hz Variable speed control box mounted on machine cabinet

– Single rail system with HDPE bottle contact surface and tool-less adjustments

(2) A Packaging Systems 15′ x 6.0″ Sanitary Conveyors

– 304 Stainless steel closed-shell construction

– 6.0″ Delrin chain belt, elevated on spacer for easier washing above & below the belt.

– Optional open link chain for faster removal.

– 115V/1f/50-60Hz Variable Frequency Drive.

– Washdown duty 90Volt DC motor.

– 36:1 gear reducer.

– Speeds up to 67′ per minute.

– Single stainless steel rail system with HDPE wear strip & tool-less brackets.