Description

System Overview

This is a fully integrated, commercial-grade bottling and packaging line engineered for wine and glass-bottled beverages. Designed for medium-volume producers, the system delivers complete automation from bottle infeed through final case sealing. Built with premium European components and stainless-steel process routing, it combines rotary filling, capsule application, label wrapping, steam finish, inkjet coding, and end-of-line packaging in a seamless, programmable layout. The entire line is visually verified, installed, and configured for consistent throughput and minimal operator intervention.

System Specifications (Integrated Capabilities)

Production Throughput

Line Speed: 1,200 bottles per hour (BPH) nominal

Container Size Range: 750 mL standard (compatible with 375–1.5L formats via change parts)

Bottle Materials: Glass (standard wine bottle formats)

Closure Support: Natural cork, synthetic cork, ROPP (if alternate cap head installed)

Label Format: Pressure-sensitive front/back/neck or full wrap

Automation & Controls

PLC-Based Line Control: Independent logic zones (filler, labeler, capper, conveyors)

Integrated HMI Interfaces: UniOP touchscreen at filler; digital counters on labeler

Line Interlocks: Emergency stops, guarding, zone feedback, and bottle presence sensors

Speed Synchronization: VFD-regulated conveyors with filler/labeler sync

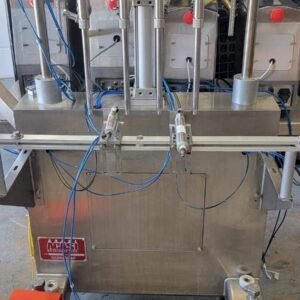

Filling & Capping

Filling Method: Rotary gravity or light-pressure fill (20-valve)

Capping Unit: 9-head turret corking system (installed)

Neck Handling: Starwheel transfer with indexed screw infeed

Capsule Application & Shrink Finish

Capsule Placement: Rotary turret with magazine-fed applicator

Shrink Finish: Dual electric shrink tunnels, controlled temp zones, inline fans

Steam System: 40kW electric boiler (Reimers), plumbed to capsule zone

Labeling & Marking

Label Application: 3-head rotary labeler (front, back, neck or wrap)

Label Registration: Optical sensor alignment with electronic tension control

Inline Printing: Inkjet date/lot coder, downstream mounted with touch interface

End-of-Line Packaging

Carton Sealing: Automatic case sealer (3M/Interpack), top & bottom tape closure

Discharge Conveyor: Integrated to case sealer, guides completed cartons out of line

Utility Requirements

Power: 480V, 3 Phase (filler, labeler, boiler, capsule), 220V/1PH (shrink, seal)

Compressed Air: 90 PSI clean dry air (capsule and labeler pneumatics)

Steam: Internal electric steam generation, no external boiler required

Operational Footprint

Estimated Length: 40–50 ft (linear layout)

Width: 6–8 ft with clearance

Required Operators: 1–2 personnel per shift (loading, supervision, packing)

Additional Features

Stainless mobile pump skid for product transfer or CIP loop

Stainless change parts, worm screws, and bottle handling tooling included

Capsule, label, and cork magazine storage integrated at each station

Ventilation hood (Fumex) routed above shrink and inkjet zones