Description

This line was used to produce a 12oz carbonated soda line using a 355ml PET mineral water bottle with 28mm child resistant caps. Sleeving was performed after with 40 or 50 gauge PET shrink sleeves.

This listing includes:

Norland Automatic Unscrambler for plastic bottles

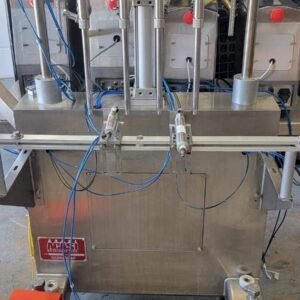

Norland Triumph Ultra bottle Filler with:

Built-in Clean Room:

– clean air conveyor before rinse station

– bottles are inverted, rinsed, and drained

– 18 rinse valves

Rotary Bottle Filling:

– OEM rates speed at up to 5,000 BPH at 500ml volume (previously ran 355ml)

– 18 fill heads

– Continual motion

– Purged with Co2 before filling for carbonated beverages

Automatic capping:

– Capable of capping bottles from 300ml to 2L (may require change parts)

– Cap elevator/feeder

– FlowTam Mixing tanks, one with mixer installed, one without (2000L capacity, approx 528 Gallons)

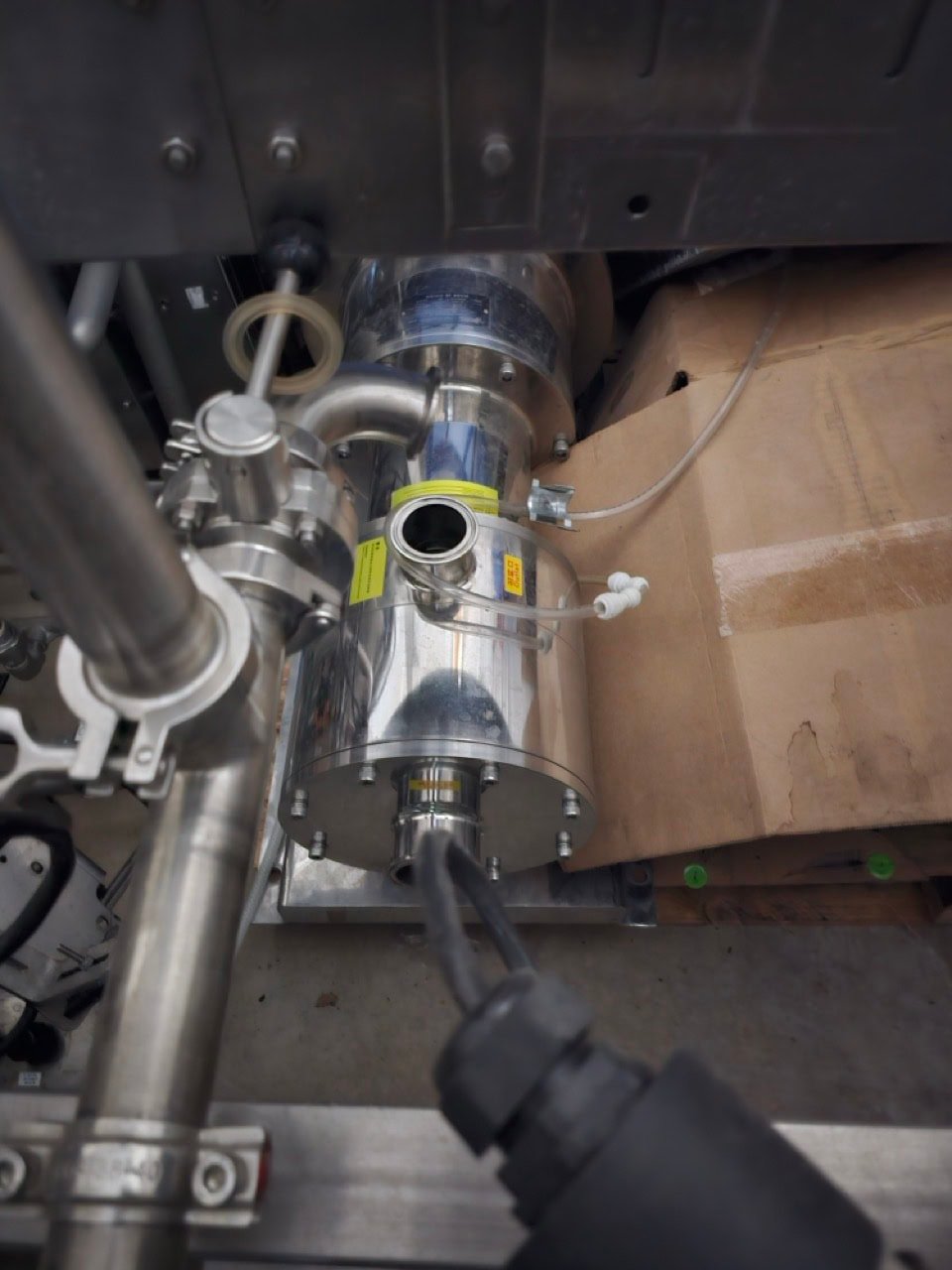

– High shear in-line mixer

– ABE CIP system w/ integrated pump (150L)

– Reimers Steam Generator

– Steam tunnel

– Accumulation table

– Accumulation/feeder table

– Assorted 316L piping

**year of manufacture between pieces may vary