Description

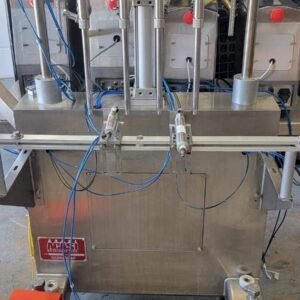

12-Head GAI Filler

GAI Labeler

12 Spout Rinser

Onboard Generator & Air Compressor

26 MM Crown Cap Closure

3,000 Bottles Per Hour

It Has Change Parts For And Can Currently Fill 187ml, 12oz, 375ml, 500ml, 22oz, And 750ml Bottles

Miles: ~59,000

Generator Hours: ~ 3,800

The truck was built to order by Prospero NW, featuring GAI monoblock bottling

equipment. With a rate of up to 250 cases per hour, big jobs are completed quickly and efficiently.

Here is how the process works:

Bottles are manually fed on to the conveyor belt to head to the labeler.

After labeling, the bottles are fed to the internal rinser. Bottles are flipped upside down, sprayed internally with sterilized water, flipped over and drained.

After rinsing, the bottles head to the filler.

The filler seals the bottles, floods them with

Co2, evacuates the C02 creating a vacuum, then fills with C02 again.

Afterwards it fills the sealed bottle with your beverage. Lastly, more Co2 is floated over the beverage to minimize head.

Bottles are then crowned.

Finally, the filled and crowned bottles are rinsed off before heading out of the truck via a conveyor belt.

Utilities needed:

CO2; Recommend a 1/2” bore, rebuildable Co2 regulator. Pressure is typically set it at

35-40psi.

Water: A standard garden hose fitting is needed. Water is used for post-rinsing the

bottles only.

Electrical: Other than our compressor, all the equipment runs on standard 110v/60hz

electricity.

Recommend at least 3 people to run the line.

** Inquire For Videos **