Description

Machine Overview

This WeighPack turnkey packaging system includes the Primo 360 16-head combination weigher, Swifty Bagger 3600 for premade pouches, cleated incline conveyor, stainless mezzanine platform with stair, rotary accumulation table, and a separate bulk hopper feed system with low-level incline conveyor. Designed for dry, granular, or free-flowing products, the system enables precision combination weighing and continuous pouch filling.

Primo 360 diagnostics show active load cells, calibrated and running with functional test logic. The Swifty 3600 is clean and fully enclosed with Lexan doors and visible pouch handling modules. Three operational videos confirm full functionality. Spare parts inventory includes OEM electrical and pneumatic components, as well as a quoted WeighPack fiber optic funnel kit.

Specifications & Features

16-head Primo 360 stainless radial combination weigher

Tool-less weigh bucket removal; washdown design

Diagnostic HMI showing active weighing per channel

Zero and full calibration, test functions, real-time weight display

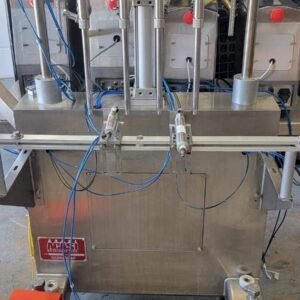

Swifty Bagger 3600 premade pouch fill/seal machine

Clear Lexan guarding, outfeed conveyor, rotary accumulation table

Blue cleated incline conveyor, stainless frame, floor to scale level

Stainless mezzanine with stair and perimeter safety rail

Twin-chamber feed hopper with lower incline conveyor system

OEM spare components included: Festo sensors, thermocouples, harnesses

Fiber optic sensor and funnel kit

Verified video evidence of full system running and bagging